Bridging the

Physical-Digital Divide

Merge Plot specializes in the design, development and manufacture of cutting-edge hardware and software solutions. Our expertise lies in advanced optics, artificial intelligence and robotics technologies. We build resilient sensor, perception, and robotic systems that enable faster and smarter action in dynamic environments.

Counter-UAS

Digital Twins

Robotics

Counter-UAS Technology

We build hardware and software designed to detect, analyze, and predict UAS activity to enhance the safety and security of military bases, strategic installations, and teams in the field.

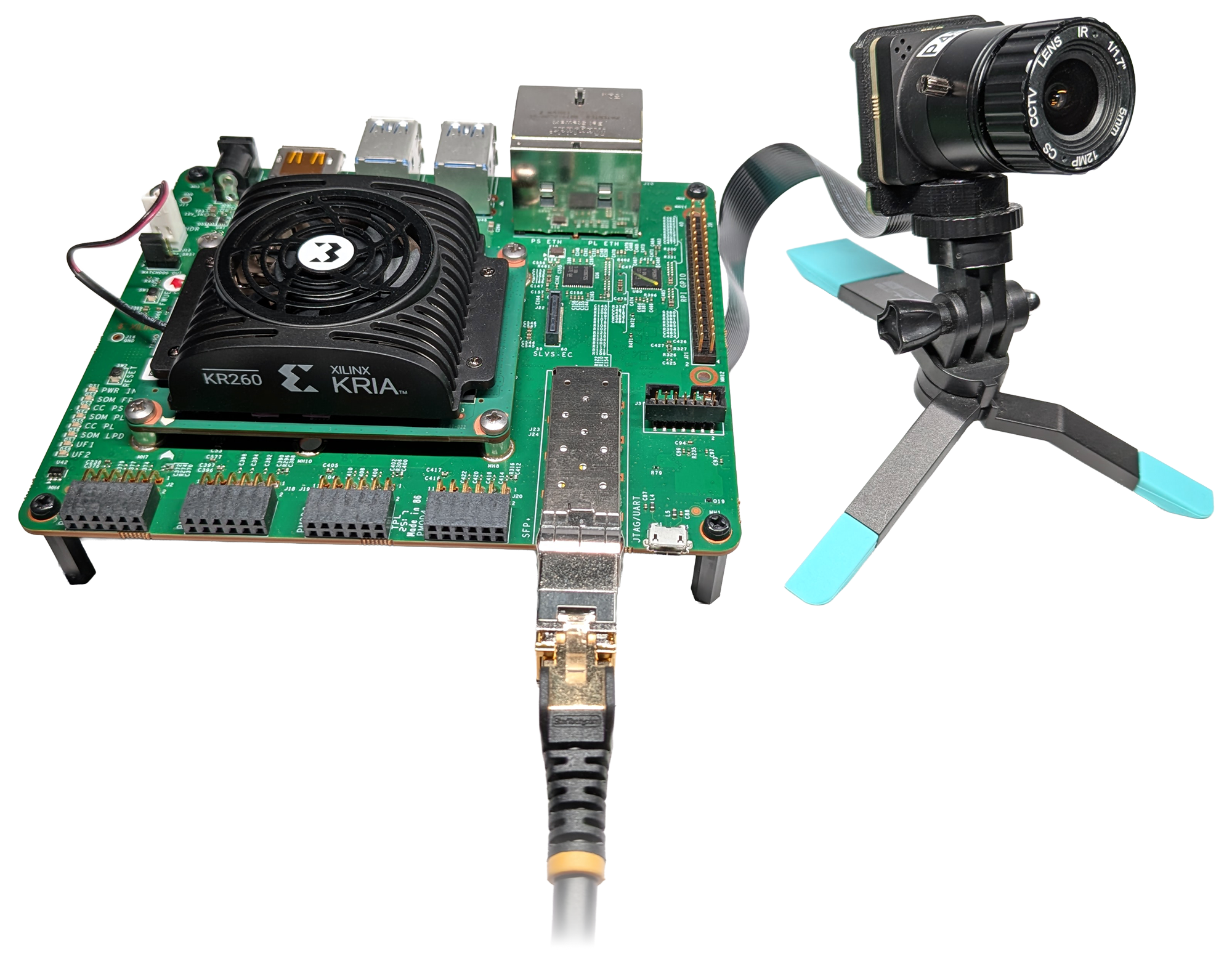

NeuroSight™

NeuroSight is a ruggedized, low-power, event-driven imaging system based on Merge Plot’s EdgeVision™ AI Board. Engineered for microsecond-level latency and extreme dynamic range, NeuroSight is designed to integrate seamlessly with AI/ ML platforms, enabling real-time detection, tracking, and control in dynamic, contested, and high-speed environments across aerospace, defense, and robotics domains.

Unlike traditional frame-based cameras, the base NeuroSight platform captures only changes in contrast based on motion using asynchronous pixel technology. The returned sparse data reduces latency, bandwidth, and power consumption while enhancing performance in high-speed and low-light conditions. The expandable platform allows for additional imaging modalities to work in tandem with the event sensor.

ATLAS

The Advanced Tactical Leadership Assistance System is a generative AI tool that automates and accelerates drone threat response by fusing leadership intent with a calculation engine to ensure the development of operationally-feasible and doctrinally-sound countermeasures. ATLAS solves the challenge of slow, manual drone threat mission planning and response, reducing operational risk in complex environments.

Digital Twins

Our digital twin technology creates living, high-fidelity models of platforms that mirror real-world behavior in near real time. It enables teams to simulate maintenance processes and optimize logistical decisions before they’re deployed in the field. Our systems reduce risk, compress iteration cycles and accelerate yield and throughput improvements.

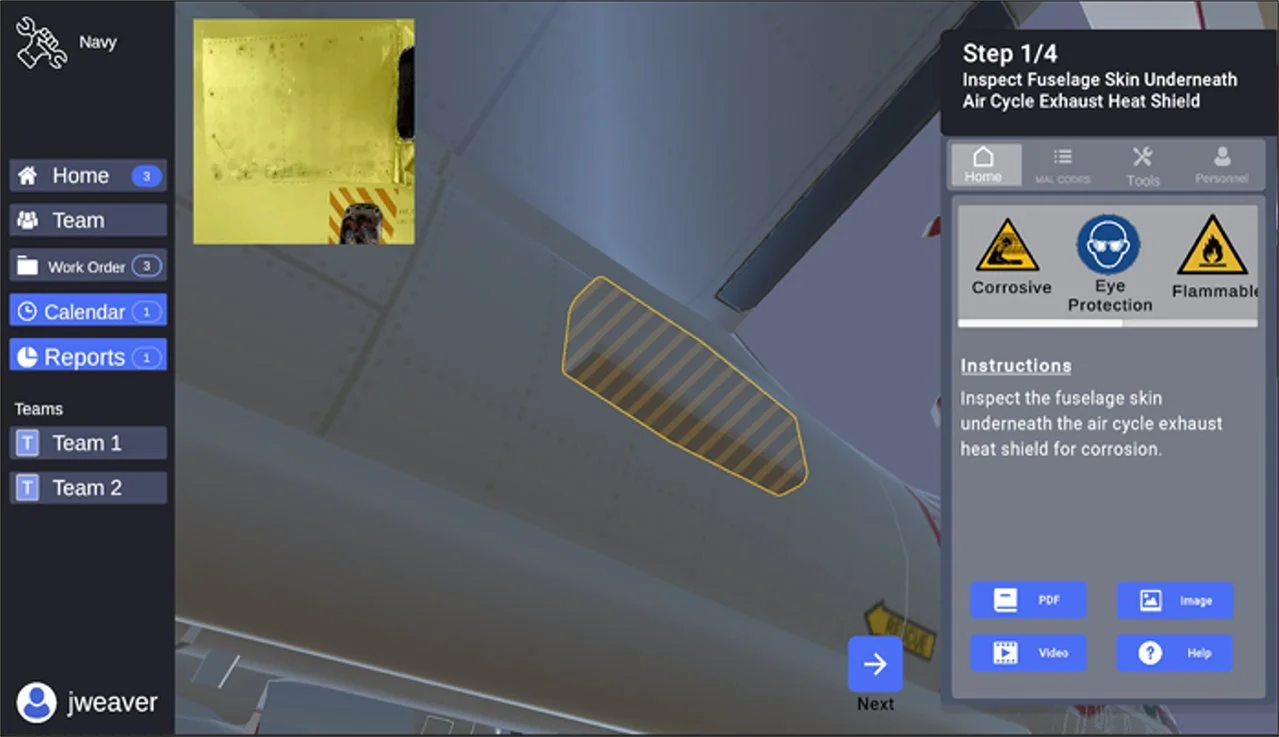

QuickTurn™

QuickTurn addresses a persistent gap in maintenance operations by replacing text-based records—which obscure the scope and location of damage such as corrosion—with spatially captured ground truth that makes asset condition visible and measurable. By building a digital twin of each platform through tablet-based scanning, QuickTurn analyzes and prioritizes condition hotspots, feeds predictive scheduling, and generates a prioritized work queue that shortens turn-times and reduces mis-allocated effort. The system enables depots to quantify corrosion across fleets for targeted repair and budgeting, units to track aircraft or platform up/down status in real time, and deployed teams to map and address damage on site. QuickTurn drives faster turnaround, clearer prioritization, and more consistent condition awareness across the force.

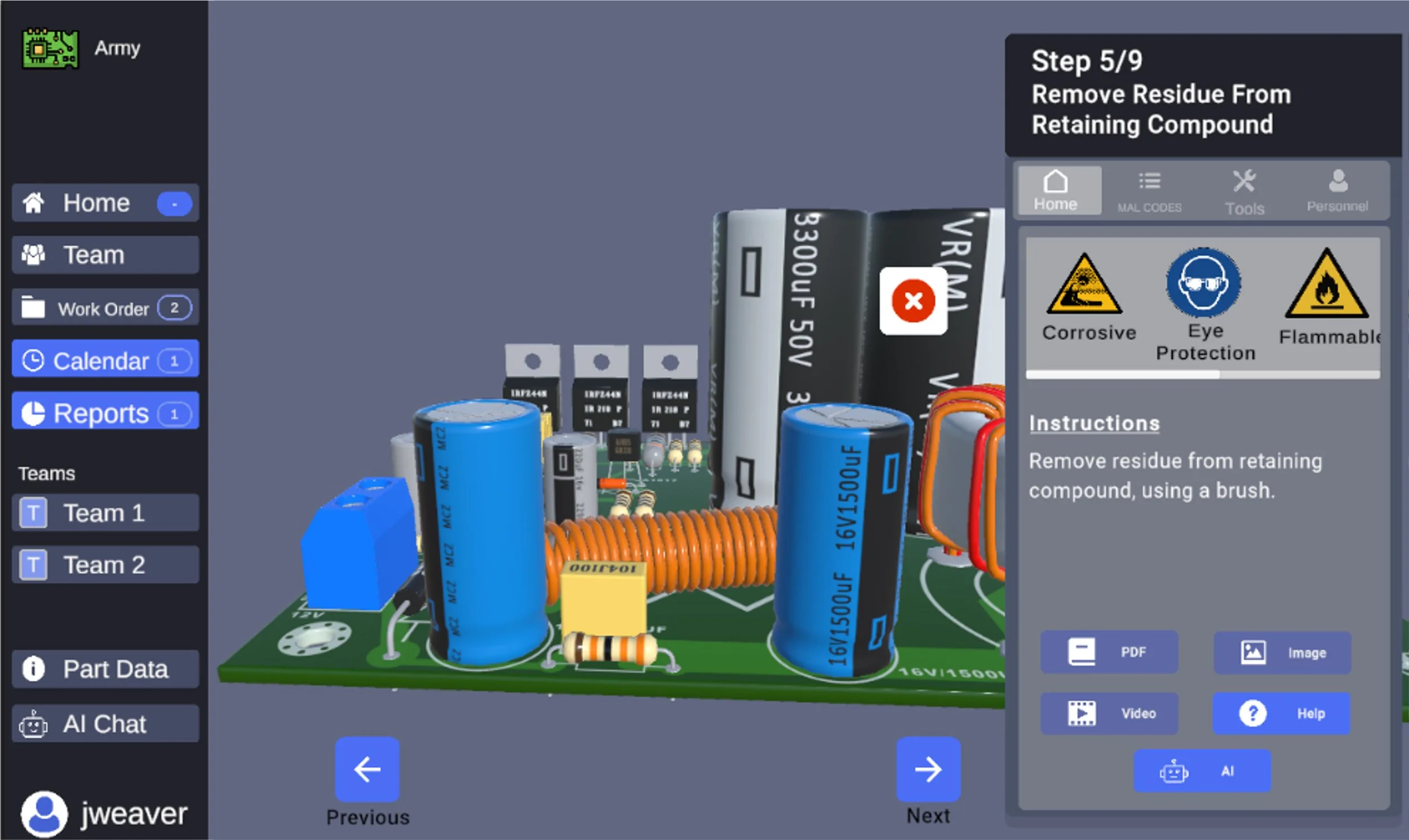

REVISE

Reverse Engineering Visualization and Simulation Enterprise (REVISE) addresses the growing challenge of sustaining legacy systems by replacing slow, labor-intensive manual reverse engineering with AI-driven automation that can reduce design re-creation time by up to 90%. As obsolete components increasingly disrupt defense readiness and industrial productivity, REVISE creates persistent digital twins that preserve engineering data for long-term sustainment and rapid re-manufacture. A mixed-reality interface connects technicians, engineers, and production teams around a shared, authoritative model, improving coordination and reducing rework. Designed as a scalable, dual-use platform, REVISE strengthens fragile supply chains while bridging the needs of defense logistics and private-sector manufacturing.

Intelligent Robotics

We bring autonomy and adaptability to expeditionary and advanced industrial environments. By combining real-time sensing, AI-driven decision-making, and tight integration with production systems, Merge Plot’s technology enables robots to handle variability, learn from experience, and execute complex tasks with precision. The result is resilient automation that scales faster, reduces manual intervention, and keeps production moving even as conditions change.

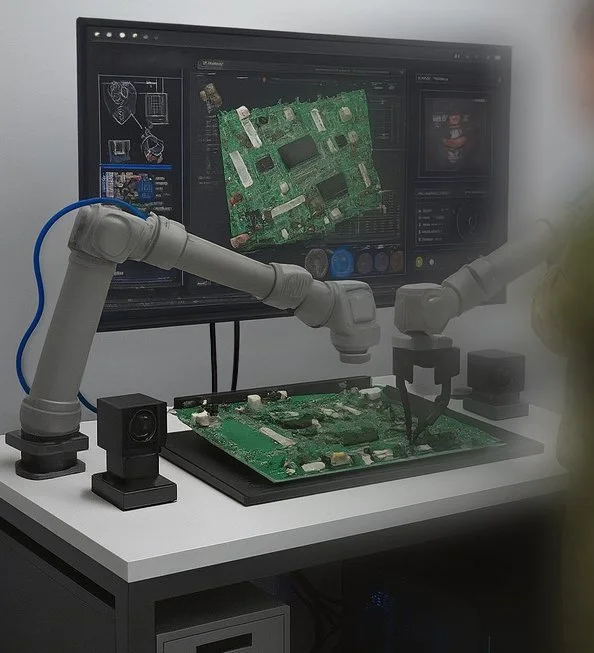

MANTIS

MANTIS is Merge Plot’s intelligent robotics platform designed to operate reliably in the most complex manufacturing environments. It enables robots to perceive their surroundings, adapt to variation, and make context-aware decisions in real time—without rigid programming or constant human oversight. By tightly integrating sensing, control, and AI, MANTIS allows automation to respond dynamically to changes in parts, processes, and conditions. This flexibility reduces downtime, accelerates deployment, and unlocks automation in scenarios that were previously impractical. The result is robotic systems that are not just automated, but operationally intelligent and production-ready at scale.

About Us

Human machine teaming is at the center of everything we do.

The term "Merge Plot" comes from military aviation, denoting the point in an intercept where friendly and adversary aircraft converge in the same airspace, rendering their radar tracks indistinguishable as models give way to reality. We use the term to symbolize the melding of the digital and physical worlds—the space where we seek to develop groundbreaking technology.

We are a Veteran-Owned Small Business primarily operating in the B2G and B2B sectors, with ongoing projects aimed at the retail market. We perform as prime contractor on several military contracts, as well as provide engineering services to third parties.